© 2024 Truss Machinery Connections, Inc.

Phone: 800-580-6430

Fax: 800-580-6424

•

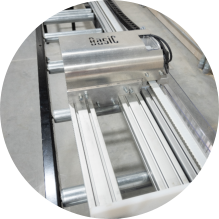

New saw design with double slides minimizing

footprint (Position it only 20" from the wall)

•

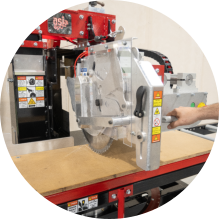

Roller slides reducing risks of injury by lowering the

effort pulling the saw

•

Hybrid aluminum-steel construction combining the

robustness of steel for the frame with the lightness

of aluminum for the moving head

•

High resistance powder coat paint surface finish

•

Blade travel adjusts automatically depending on the

saw angle

•

5 HP motor with integrated mechanical brake

•

Minimum Angle of 7 Degrees with 26" Stroke

•

18in saw blade

•

6in cutting height

•

Complete (wrap around) Blade Guard

•

4in dust collector connection

•

Optional infeed and outfeed conveyors and

supporting stands

•

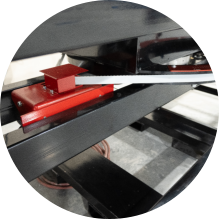

Steel reinforced polyurethane positioning belt

ensures accuracy

•

Up to 15°/sec. Angulation

•

Can be connected to your network to upload the

cutting lists directly to the computer

•

Saw files read: EHX, TRS, XML, EZY, CYB, WCD,

ASI

•

Length and/or angle automation system.

•

Up to two (2) high resolution, high speed & high

torque servo motors for accurate positioning with

integrated Schneider-Electric drives.

•

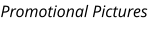

20in Lenovo touchscreen SSD computer with

BasiC software and Windows 11 Pro OS

•

Easy axis by axis calibration.

•

Manual & semi-automatic modes

•

Printing System for marking plates and most

printable parts (3 or 4 pen options)

© 2024 Truss Machinery Connections, Inc.

Phone: 800-580-6430

Fax: 800-580-6424

•

New saw design with double slides minimizing

footprint (Position it only 20" from the wall)

•

Roller slides reducing risks of injury by lowering

the effort pulling the saw

•

Hybrid aluminum-steel construction combining

the robustness of steel for the frame with the

lightness of aluminum for the moving head

•

High resistance powder coat paint surface finish

•

Blade travel adjusts automatically depending on

the saw angle

•

5 HP motor with integrated mechanical brake

•

Minimum Angle of 7 Degrees with 26" Stroke

•

18in saw blade

•

6in cutting height

•

Complete (wrap around) Blade Guard

•

4in dust collector connection

•

Optional infeed and outfeed conveyors and

supporting stands

•

Steel reinforced polyurethane positioning belt

ensures accuracy

•

Up to 15°/sec. Angulation

•

Can be connected to your network to upload the

cutting lists directly to the computer

•

Saw files read: EHX, TRS, XML, EZY, CYB,

WCD, ASI

•

Length and/or angle automation system.

•

Up to two (2) high resolution, high speed & high

torque servo motors for accurate positioning with

integrated Schneider-Electric drives.

•

20in Lenovo touchscreen SSD computer with

BasiC software and Windows 11 Pro OS

•

Easy axis by axis calibration.

•

Manual & semi-automatic modes

•

Printing System for marking plates and most

printable parts (3 or 4 pen options)